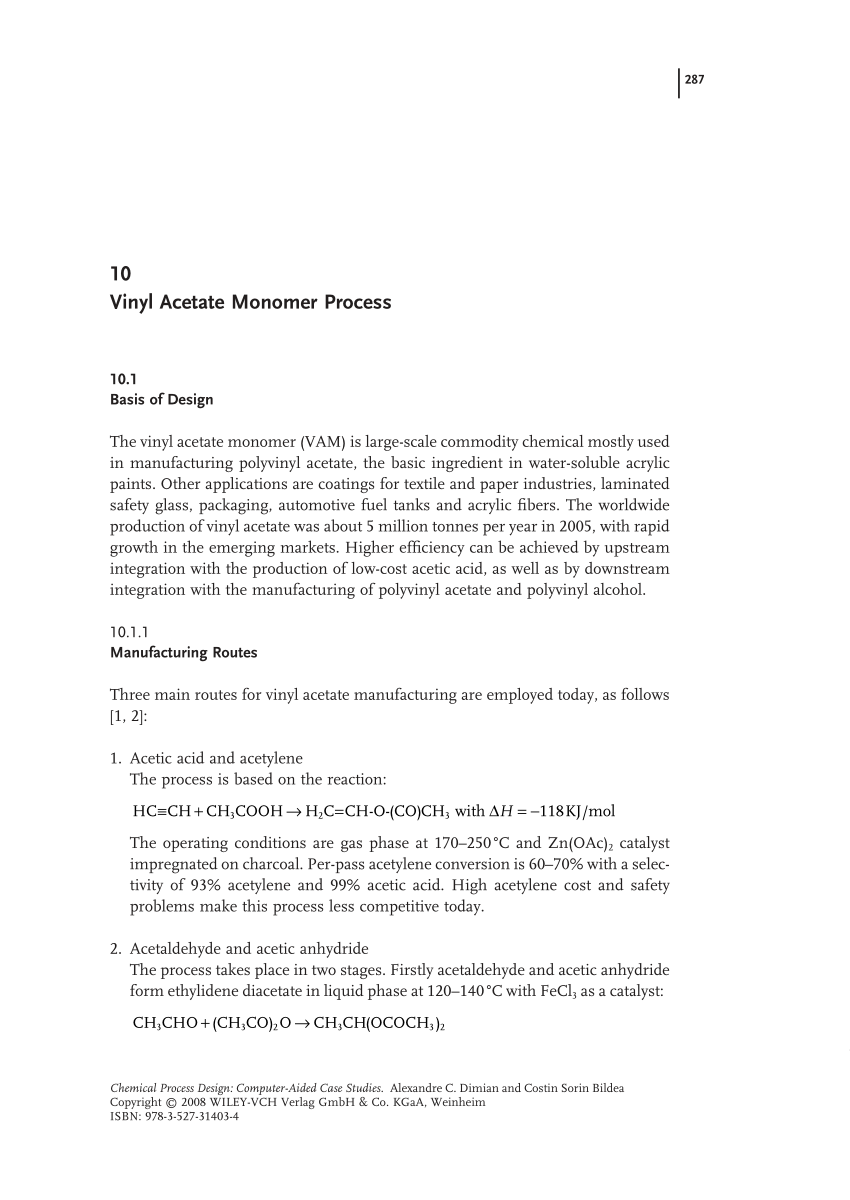

An industrial design control study for the vinyl acetate monomer process.

An industrial design control study for the vinyl acetate monomer process.

An industrial design control study for the vinyl acetate monomer process comput.

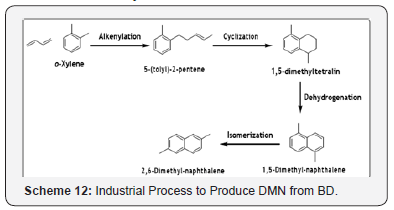

This monomer is used principally in the production of polyvinyl acetate pvac and other vinyl acetate co polymers.

Tyréus this work presents design details of an industrial process for the manufacture of vinyl acetate monomer.

Plant design for the production of vinyl acetate free download as powerpoint presentation ppt pptx pdf file pdf text file txt or view presentation slides online.

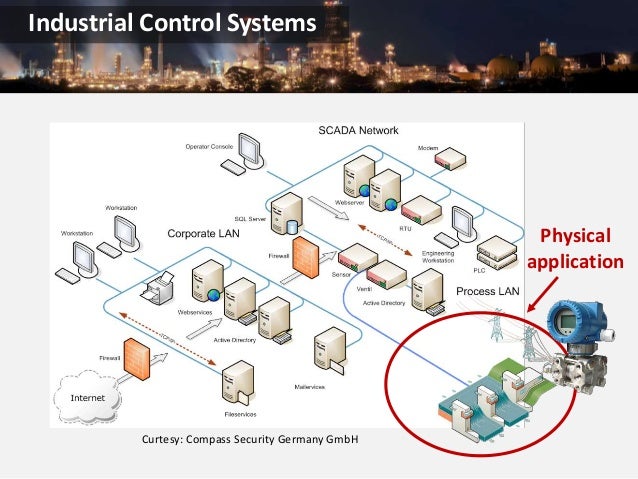

This plant model enables the users to experience realistic plant operation since it reflects the real plant characteristics and practical problems on the basis of experienced practitioners opinions.

More importantly the plant model provides a new benchmark problem.

A simulation of a vinyl acetate monomer vam process design was developed and compared with the work of luyben and tyreus 1998luyben m.

This paper presents design details of an industrial process for the production of vinyl acetate monomer and thus goes a step beyond the eastman process control challenge problem.

Polyvinyl acetate is a precursor of polyvinilyc alcohol and polyvinyl acetate resins pva.

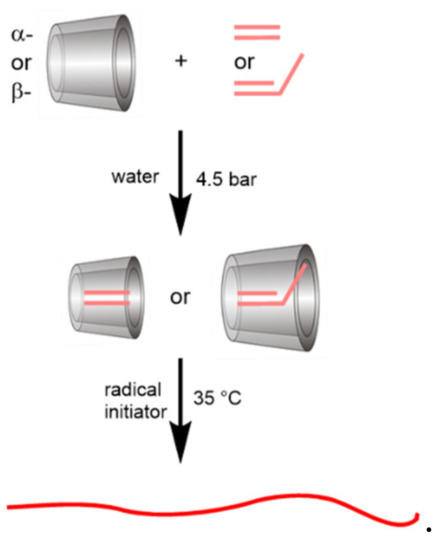

The vinyl acetate monomer vam process presents several challenging design problems because of the many design optimization variables and several important constraints.

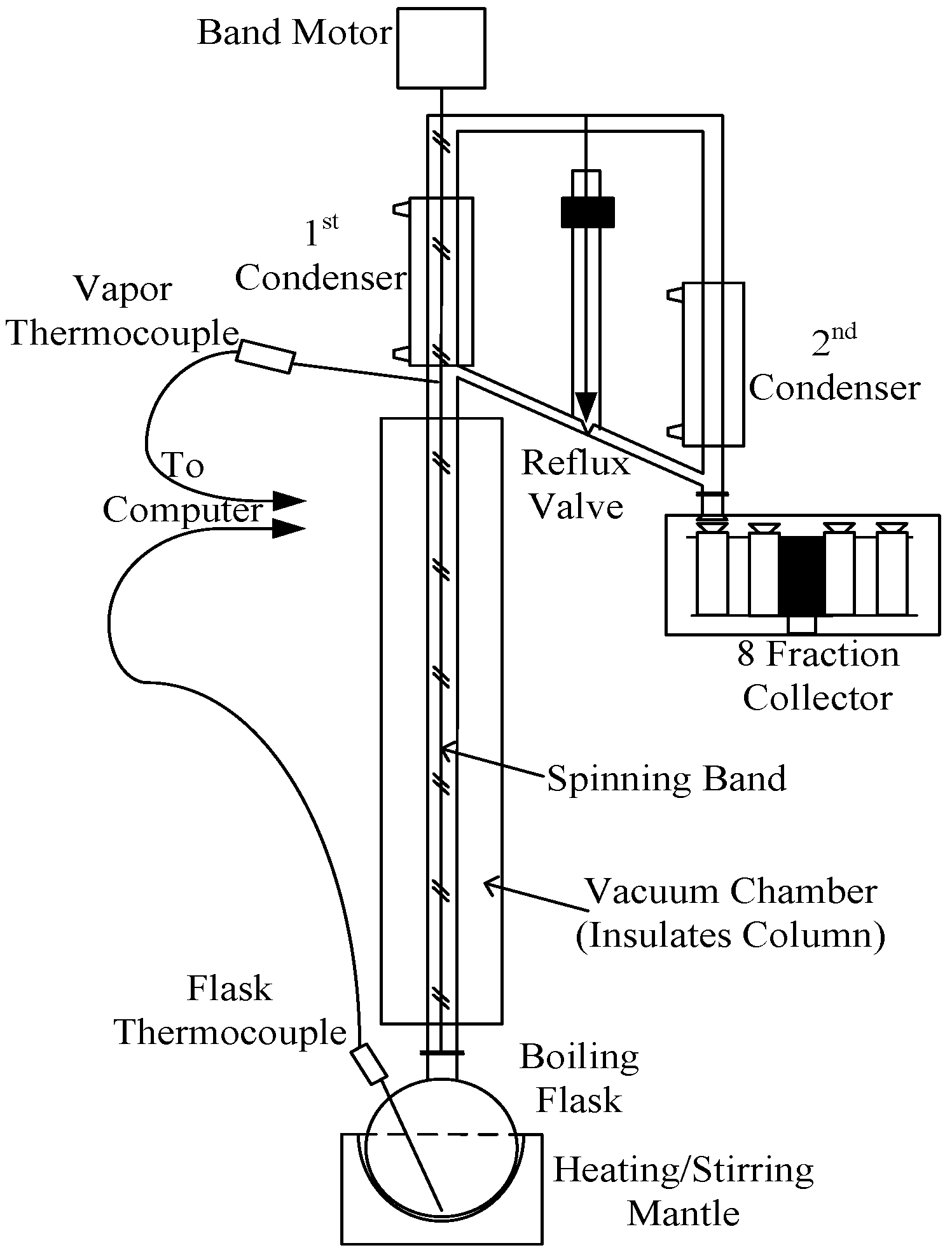

The process features a cooled tubular reactor both gas and liquid recycle streams two absorbers and two distillation columns one involving heterogeneous azeotropic distillation.

Our purpose is to offer a realistic example that is uniquely suited for.

The alternatives included the implementation of a new reboiler level control strategy a static feedforward ratio control.

The reaction loop section of the vinyl acetate process contains a ßowsheet and unit operations that are typical of many chemical plants ithas bothgasandliquidrecyclestreamswith.

The reaction loop section of the vinyl acetate process contains a flowsheet and unit operations that are typical of many chemical plants.

A simulation of a vinyl acetate monomer vam process design was developed and compared with the work of.

This paper presents design details of an industrial process for the production of vinyl acetate monomer and thus goes a step beyond the eastman process control challenge problem.

Dynamic simulation of a vinyl acetate monomer process design has been suc cessfblly used to test alternative plantwide control strategies.

Abstract a rigorous dynamic plant model of a vinyl acetate monomer vam production was developed.